technology

How ALPIS™ works

We employ aerial LiDAR leak detection with a laser tuned to the main absorption band of the hydrocarbon of interest. Sounds complicated but it's actually quite simple. LaSen has developed a payload that employs lasers tuned to the absorption bands of methane and other hydrocarbons. The system is mounted to an airborne platform: helicopter, airplane, or UAV. Laser energy is projected at the asset from a calculated altitude. When the laser beam passes a fugitive hydrocarbon plume, the plume absorbs a finite quantity of laser light. Thus the laser return is diminished and the exact location of the methane leak marked precisely with GPS coordinates. The location of the leak is also marked on a map with HD pictures of the indication.

The eye-safe laser beam is transmitted down from the aircraft to illuminate the area on the ground above and around the buried pipe, 400 times per second. The laser foot print is 1600 sq ft.

If the eye-safe laser beam encounters gas emanating from a leak, the received energy will be diminished due to the absorption of laser light by the plume. There is no need to fly through the plume. ALPIS will detect the leak from a safe altitude of 300 to 500’ AGL.

The light reflected from the ground is collected by the sensor’s receiver, and the amount of received energy is measured.

This absorption signature is used to locate the leak and to quantify its magnitude.

Reliable? How about 100x more sensitive than our nearest competitor.

As you can see, our mid-IR wavelength far exceeds the performance of any ground-based or airborne remote sensing technology on the market. When we say “let’s go find it” we mean it.

The laser used in ALPIS™ (Airborne LiDAR Pipeline Inspection System) operates in the Mid IR wavelength (3300 nm) providing 100X more sensitivity than all competing technologies. Competing technologies operate in the near IR (1650 nm).

Need to geek out even more?

Excerpt from “Mid-IR Tunable Lasers Probe Hydrocarbon Molecules” by Lockheed Martin Aculight scientist Angus Henderson:

The strength of the fundamental absorptions in this so-called “C-H stretch” region can be orders of magnitude higher than overtone absorptions of the same molecules in the near-infrared (<2-μm wavelength). For example, the absorption of methane at 3.3 μm is more than 100 times stronger than in its overtone band at 1.65 μm (Figure 1). As a result, narrowband tunable lasers operating in the C-H stretch region can be used to perform highly sensitive detection of hydrocarbon species, as well as more fundamental investigations of molecular structure and chemical reactions.

Click below to read the science behind photonics, mid-IR tunable lasers, and methane absorption strength vs. wavelength.

Payload Principles

LaSen’s ALPIS™ operates on the basis of a mid-infrared Differential Absorption LiDAR (DIAL) chemical sensor. The principle of DIAL relies on the selective absorption of laser light by different chemicals. The mid-infrared laser used in the ALPIS™ system is particularly well suited for detection of hydrocarbons such as methane, propane, and butane, as well as volatilized liquid petroleum products.

ALPIS™ System Components

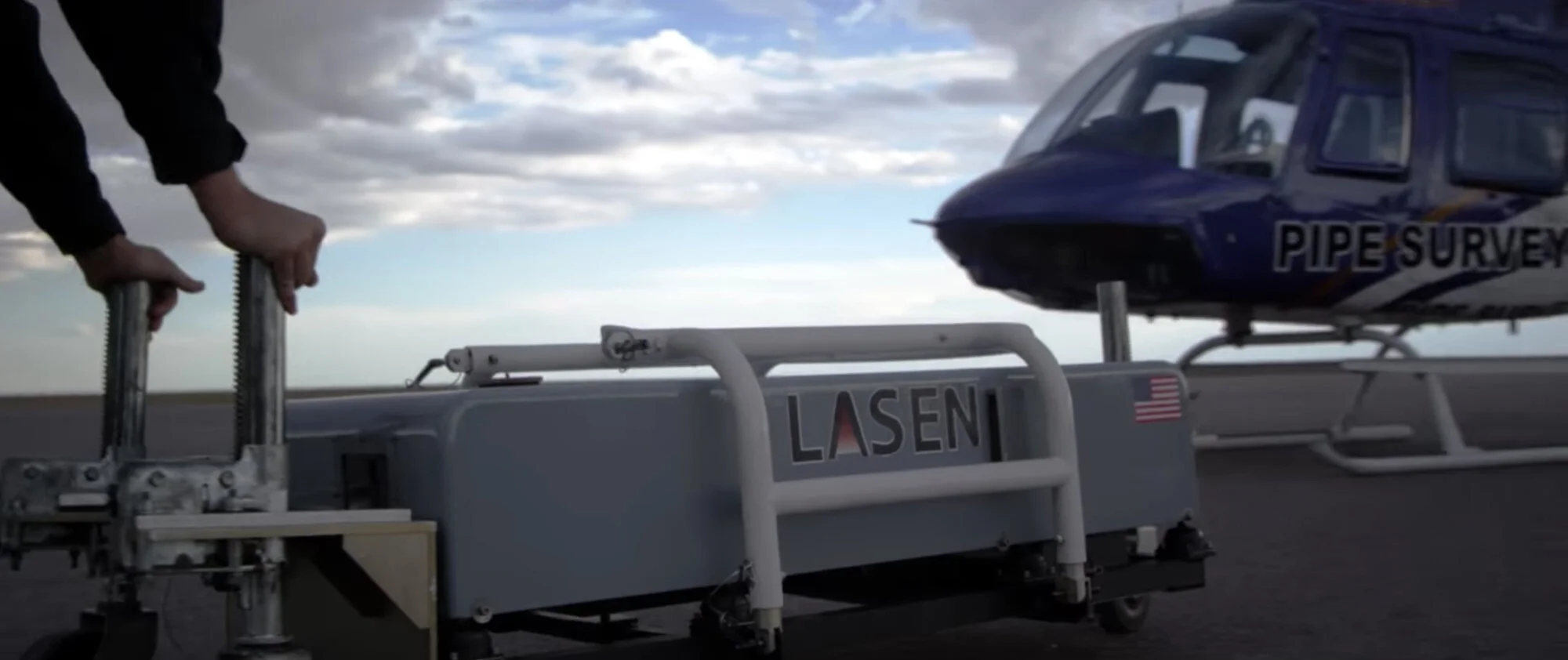

ALPIS™ is comprised of an airborne sensor unit and operator’s console.

The sensor is mounted to our Bell Jet Ranger helicopters.

Weighing in at 250 lbs, the payload is light enough to allow the crew and one pipeline observer on-board during a typical mission.

The main sensor enclosure houses the eye-safe laser, computer, receiver optics and detectors.

In addition, the system is equipped with a high resolution imaging cameras and a GPS receiver.

The combination of an eye-safe laser sensor, imaging and GPS data makes it possible to precisely locate hydrocarbon leaks.

The sensor takes 400 readings per second and checks it’s calibration once every second.

An operator, present on every flight, controls the system using a standard laptop interface and verifies the integrity of the data.

LASER ILLUMINATION

1,600 square feet that illuminates the ROW 400 times per second

UNMATCHED LASER SPEED

Laser at 400 hertz, more than double our competitor's

UNMATCHED DETECTION ACCURACY

Capable of detecting the smallest leaks down to 5 PPM

ASPEN AVIONICS

Real time data on wind speed and direction

PipeVision

LaSen has recently updated it's entire fleet of LiDAR sensors, which are lighter and more technologically advanced, into service. The units employ a new PipeVision™ video camera that provides high resolution video of more than 800 feet of your right of way at their widest angle and is tied to continuous GPS location. This video will allow our customer to document the status of their right of way, from the above ground facilities to potential encroachments, vegetation, erosion threats, and the critical terrain features such as water crossings and wetlands. LaSen customers will receive both the standard inspection data plus the new video to advance their pipeline safety/integrity programs.

ROW Inspection

High Resolution Video for Visual Inspection

Maximum Coverage

Camera captures 800 ft of ROW at widest angle

ROW Compliance

Identify potential encroachments, vegetation, erosion threats ...

Aspen Avionics

We have now integrated Aspen systems into our helicopters that give us real time data on wind direction and speed. Using the Aspen systems, along with our industry leading 1,600 sq. ft. footprint on the ground, we can fly with precision accuracy directly above the pipeline or stay slightly downwind if required, locating any possible indication better than any competitive system on the market.

Professional-Grade Electronic Flight Instrument System (EFIS)

Airspeed and altitude tapes, with altitude alerter

Built-in GPS Steering

Base map with flight plan legs and waypoints, curved flight paths

ADAHRS

Integral Air Data Computer and Attitude Heading Reference System